The Future of Enterprise Software: How HxGN EAM is Revolutionizing Industries

In the constantly evolving realm of technology, enterprise software stands as one of the paramount pillars shaping the business world. But as with all sectors, change is a given, and in the enterprise arena, that change is both swift and transformational. And who’s leading this change, you ask? HxGN EAM.

Enterprise Software: The Ever-evolving Landscape

The demands of the modern business environment have steered enterprises towards more robust, flexible, and scalable software solutions. To stay afloat and ahead, industries need a software platform that not only addresses their present needs but also anticipates future challenges. Enter: HxGN EAM.

HxGN EAM: The Game Changer

HxGN EAM isn’t just another entry in the enterprise software realm. It’s a revolutionary platform that's setting unprecedented standards. Here’s how:

- Scalability: Whether you’re a budding startup or a global conglomerate, HxGN EAM adjusts and scales according to your business size and demands, ensuring efficiency at every step.

- Integration Excellence: Modern businesses aren’t standalone entities. They’re interconnected systems. HxGN EAM boasts seamless integration capabilities, linking departments, processes, and data effortlessly.

- Customization Galore: No two businesses are the same. Understanding this, HxGN EAM offers vast customization options. Whether it's tweaking features or aligning processes, the platform molds itself around your enterprise, not the other way around.

HxGN EAM in Action: Real-world Applications

From healthcare to manufacturing, HxGN EAM is proving its worth. Hospitals are managing assets more efficiently, ensuring critical equipment is always in top condition. Manufacturers are reducing downtime, ensuring productivity remains unhindered. The success stories are countless, testament to HxGN EAM's unmatched capabilities.

Looking Ahead: The Bright Future of Enterprise Software with HxGN EAM

The trajectory for HxGN EAM is crystal clear: upward and forward. With continuous upgrades, holistic support systems, and a user-centric approach, it’s poised to redefine enterprise software standards in the coming years.

As industries continue to grow and evolve, having a reliable, efficient, and forward-thinking enterprise software becomes indispensable. And with HxGN EAM leading the charge, the future looks promising.

Conclusion

The winds of change in the enterprise software sector are blowing strong, and riding those winds is HxGN EAM. As businesses globally are witnessing a fundamental shift in operational efficiency and process alignment, it’s clear that this platform is not just meeting expectations - it’s setting them.

So, whether you’re in the market for a new enterprise software solution or just curious about the future landscape, keep a close eye on HxGN EAM. The revolution is here, and it’s reshaping industries one module at a time. Our experienced team at DigitalThinker is here to support you through every step of your HxGN EAM journey. From implementations to customizations and training, we provide the expertise and guidance you need to unlock the full potential of HxGN EAM. Contact us today!

If you’re looking to delve deeper into the world of enterprise software and HxGN EAM, stay tuned to our blog and check out our STREAMLINE ASSET MANAGEMENT USER CONFERENCE. We’re committed to bringing you the latest, most insightful content on industry trends, tips, and innovations.

Harnessing the Power of Python: Revolutionizing EAM Capabilities with HxGN EAM's Flex Python Framework

In a blog post by Julio Roque, VP of Software Development at Hexagon. He wrote about how HxGN EAM's Python studio extends the HxGN EAM application. Making it an excellent choice for automating tasks, building on the application, and creating custom functions. Let's delve into the benefits of Python for EAM applications and how HxGN EAM's Flex Python takes it to the next level.

Unlocking the Potential of Python for EAM:

- Ease of Use: Python's simple syntax enables EAM users to quickly contribute to EAM projects. The reduced learning curve ensures a seamless adoption of Python scripts for various tasks, streamlining workflow creation and troubleshooting within EAM projects.

- Increased Flexibility: Python's robust developer community provides a treasure trove of libraries and frameworks that can be utilized to extend and customize EAM projects. With access to these resources, HxGN EAM users can tailor solutions to meet their specific needs.

- Improved Efficiency: Now EAM users can automate tasks, enhancing the overall efficiency of their EAM workflow. This translates to optimized processes and better time management, allowing teams to focus on strategic initiatives.

HxGN EAM's Empowering Python Framework:

HxGN EAM goes the extra mile in harnessing the potential of Python through its fully integrated Python framework, which comprises two major components:

- HxGN EAM Python Studio, powered by JupyterLab: A comprehensive scripting environment leveraging Python 3 scripts, providing access to Python's extensive libraries, APIs offered by HxGN EAM public, rest and soap APIs.

- HxGN EAM Flex Python infrastructure: A powerful Kubernetes-based platform that runs Python scripts with minimal performance impact on HxGN EAM. This addition ensures smooth execution, enabling users to tap into the full power of Python without affecting performance.

Unleashing the Possibilities with HxGN EAM Flex Python:

The power of HxGN EAM's Flex Python opened the door to endless possibilities. From simple Python scripts which enhance EAM functions to complex machine learning models for predictive analytics, or even triggering work orders based on weather alerts.

Using Python for EAM users to write scripts quickly and easily connect with other technologies. Making EAM solutions become more effective to meet unique business standards.

Conclusion:

Flex Python allows EAM users to master their operations, processes, and propel performance to new heights.

Exploring the endless possibilities, Python's introduction to Enterprise Asset Management, powers organizations to take on challenges and seize opportunities.

Avoiding These Common Maintenance Department Mistakes

A well-functioning maintenance department is the backbone of any organization. Certain mistakes can prevent of your teams' goals. At DigitalThinker, we believe in helping businesses to maximize their potential. Let's explore the top three common maintenance department mistakes and how to avoid them.

-

Neglecting Preventive Maintenance:

Waiting for equipment to break down is a costly mistake. To take action embrace preventive maintenance strategies to save costs and prevent unexpected downtime. By setting time for regular inspections and repairs, you can identify potential issues early and ensure that your equipment remains in peak condition.

-

Poor Data Management:

Keeping crucial records out of place can lead to angry employees. If you've ever run into walls while finding data, you understand the problems it causes. Invest in a robust asset management system to help collect, store, and get data. Digital solutions, like our cutting-edge maintenance software, centralize all relevant data, making it available for your team. With organized records at your fingers, you can make informed decisions, plan effectively, and optimize your maintenance processes.

- Skimping on Training:While a well-equipped team is a valuable asset, neglecting employee training can hinder their growth and productivity. Visit DTI Academy Now

At DigitalThinker, we understand that a well-oiled maintenance department is crucial for your success. By pointing out these common maintenance department mistakes and investing in new strategies, data management, and employee training, you can elevate your team to new heights. Let us help you take control of your operations and unlock your team's full potential.

Top 5 Tips for Maximizing your Business's HxGN EAM Investment

At DigitalThinker, we're here to ensure you're maximizing the value of your HxGN EAM investment. Let's explore five essential tips that will help you get the most out of your asset management journey:

- Align with Your Business Goals: Your asset management strategy should be tightly aligned with your broader business objectives. By doing so, you drive efficiency, reduce costs, and amplify the impact of your assets.

- Optimize Maintenance Processes: Preventive and predictive maintenance techniques are key to keeping your assets in prime condition. By implementing these strategies, you minimize downtime, improve asset performance, and extend their lifespan. Your bottom line will thank you!

- Embrace Data-Driven Insights: With HxGN EAM, you have a treasure trove of data at your fingertips. Dive into the metrics, track performance trends, and extract valuable insights. Armed with this knowledge, you can make informed decisions that drive continuous improvement and operational excellence.

- Train and Engage Your Team: Equip your team with the knowledge and skills they need to fully utilize the capabilities of HxGN EAM. Investing in comprehensive training programs fosters a culture of collaboration and ownership, empowering your team to make the most of this powerful asset management solution. Visit DTI Academy Now

- Stay Up-to-Date with Enhancements: HxGN EAM evolves to meet the ever-changing needs of asset management. Stay in the loop about the latest updates and enhancements, and embrace new features and functionalities to drive efficiency and innovation within your organization.

Bonus Tip! Choose DigitalThinker: Our experienced team at DigitalThinker is here to support you every step of the way. From implementations to customizations and training, we provide the expertise and guidance you need to unlock the full potential of HxGN EAM. Contact us today!

Canfor Southern Pine

The Challenge: Canfor Southern Pine purchasing to and from Hexagon EAM to JD Edwards

The Solution: Canfor implemented the Hexagon Webservices Connection Toolkit

Industry: Lumber Manufacturing

# of Active Equipment Records: 5,873

Products: Hexagon EAM Enterprise Edition

Product Add-ons: Hexagon Webservices Toolkit

The Result/Benefits: The AP Department is able to continue using JD Edwards for purchasing/tracking financials while sites using EAM are able to use the Purchasing Module and not have to double enter data into 2 different systems.

The Specifics: For Canfor Southern Pine to integrate the 2 applications, there are 3 custom grids (GL Custom Grid, PO Receipts for Parts, PO Receipts for Services) that are built and used to push purchasing information and inventory transactions from EAM to JDE. All Suppliers are in the common (*) org and the supplier codes mirror JDE. Units of Measure were also updated so they matched the UOMs that JDE allowed.

Omni Baking Company

The Challenge: Omni Baking Company Needs to Attach Food Safety Check sheet to Work Orders in Mobile App

The Solution: Omni Baking introduces Flex Business Rules

Industry: Food and Beverage

# of Active Equipment Records: 1,711

Products: Hexagon EAM Enterprise Edition

The Result/Benefits: When a work order is created in EAM, it is generated with a checklist. This checklist contains all the Food Safety required items for compliance.

The Specifics: After Omni Baking Company went paperless with EAM, by using the Hexagon Mobile App. We needed a way to attach a Food Safety Checklist to all Work Orders. Requiring an employee to complete one with every work order assigned. This is a regulatory requirement for food production.

Using a Flex Business Rule on every work order created to set on Post Insert to insert an Activity (Sequence 5 so it is always the first activity). The Activity has a Task Plan with a checklist. Taking the old, required document and converting it into a checklist, that uses YES/NO questions. The result is the Food Safety Checklist being a required checklist on every WO in EAM. Omni Baking Company employees use tablets to complete the checklist and close the work order.

4 Things You Should Know About Hexagon EAM

If you are in charge of an industrial manufacturing business, then without a doubt you are always seeking ways to advance its efficiency alongside its productivity—and much of that relies on your maintenance strategy.

Here at DigitalThinker, we are big proponents of preventative maintenance and in this post, we are going to examine how it is key to monitor your assets in such a way where you are able to identify and correct problems prior to equipment failure—and how preparing and predicting the future has a foundation centered on your ability to harness your data collection practices today.

The Objective

Within the industrial manufacturing sector, the objective of maintenance is always focused on guaranteeing equipment reliability and uptime. It is imperative that you know how machines are working, when they are toeing the line in terms of limitations, and when new equipment must be budgeted for and purchased.

However, accurate equipment forecasting requires data capture, identification, and review within your EAM platform. When you are able to truly understand the data that a platform like Hexagon EAM places at your fingertips, that is when you are able to realize high-quality performance.

So, how do you get to a place where you are able to predict the potential for breakdowns prior to them happening? How do you collect and study data to attain insight that enables improved decision making?

Consider these 4 critical steps you need to take right now in the development of a proactive maintenance program.

-

Data Capture:

It’s never a bad time to start collecting data. And at this point, don’t worry about what to do with it, just start gathering it. Begin small and build upon that. For instance, begin scheduling bearing temperature or pump pressure checks. Plan these out at regular intervals and record the measurements while also sticking to the schedule. If you are able to capture real-time data via your EAM platform, then this allows an advanced approach and will improve your accuracy.

-

Evidence Review:

Once you have your data in hand, study it. Check to see if any patterns are visible that could present an issue or align with operational problems you have been experiencing. And ultimately, the longer that you engage in data capture, the more knowledge you are going to be able to glean when you review it. You will be able to compare data you capture with historical data sets where failures have occurred.

-

Identify Opportunities for Improvement:

After you analyze your data, then you can begin to make predictions about where failure could occur, and you can improve your decision making—in real-time no less—and ultimately avoid machine failure and the downtime that accompanies it. Allowing you to prioritize equipment that needs to be repaired, ensure critical operations are covered, and augment specific operating processes. Once on top of it, you will be able to better plan for downtime and there will be fewer surprises and emergencies.

-

Evaluate:

At the end of the day, your data is only as good as your process is for using it. To truly understand its power, it is necessary for you to visualize and understand it. This means being consistent in your processes, taking time to evaluate what the data is telling you, and then, create your own hypothesis on where problems could lie. And if you have the potential to better use the platform you are collecting data on, then all the better.

To learn how you can take better advantage of Hexagon EAM and its capabilities, or to simply understand how this platform could improve your business, reach out to the team at DigitalThinker today. We are passionate about helping manufacturing organizations get the most bang for their Hexagon EAM buck, and we would love to help your organization be successful.

MRO Inventory and Purchasing

MRO Inventory and Purchasing

MRO inventory and purchasing are the single biggest maintenance support functions that contribute to low maintenance productivity.

Many maintenance labor delays are related to issues concerning materials and spare parts. Because the purchasing function typically procures the materials for the MRO storerooms, it also has a big impact on maintenance productivity. Additional material problems that impact labor productivity include late deliveries from vendors, wrong parts delivered, and parts that are damaged and cannot be used when they arrive.

Once the basics are in place for MRO inventory and purchasing, it is always valuable to reevaluate the processes for possible areas of improvement. The following are 2 areas that can be investigated for possible improvements to maximize the investment in the MRO inventory.

1. The use of Closing Codes & Root Cause Analysis

When the maintenance department performs accurate root cause analysis of breakdowns, it reduces the number of repetitive replacements that occur. In many organizations, the maintenance department is constantly changing spare parts. If the root cause analysis is properly performed, the number of repetitive replacements will decrease. In turn, ensuring that the maximum life is achieved for each component or spare part will decrease the MRO budget.

2. Standardized PM procedures

Another process for the maintenance department that can have a dramatic impact on spare parts costing is preventive maintenance. The more standardized that the preventive maintenance procedure is, the less variance there will be in how the preventive maintenance is performed. This performance improvement includes the material usage. If the PM program is standardized, then when the PM is forecast, the materials to be consumed can be forecast as well. Better forecasting will allow the MRO inventory and purchasing personnel ample time to order the materials and have them on hand.

Performance Indicators

It’s also essential to examine performance indicators that will insure proper management of the stores and procurement functions for maintenance. One such KPI is Inactive Stock Showing No Movement in the last 12 Months.

This indicator is used to find spare parts that are no longer needed. These items may have been purchased as spare parts for equipment that is no longer in the plant. Occasionally items were purchased in large quantities on a one-time basis, possibly for construction or a project, but were not used and have no further use at the plant or facility. Eliminating these items reduces the inventory value and the subsequent holding cost the company must pay.

Inactive Stock Line Items / Total Stock Line Items

As seen by the formula, this indicator measures the number of line items that are inactive divided by the total number of line items carried in the inventory. The percentage shows the opportunity for improvement by eliminating line items from the store inventory.

In conclusion — MRO spare parts account for an average of 50% of the maintenance budget. It is the second most important function in maintenance (first being preventive maintenance) management.

Criteria In Identifying Your Critical Spare Inventory

Critical Spares Criteria

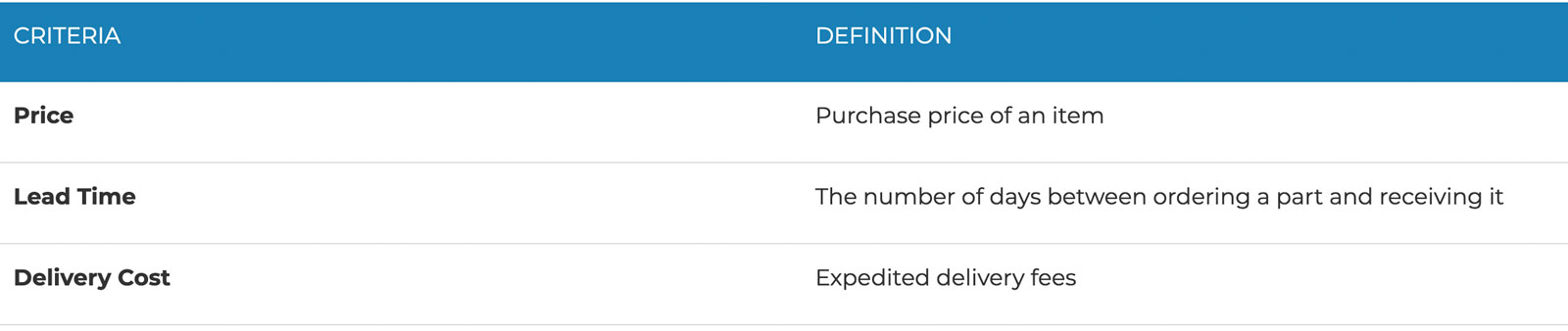

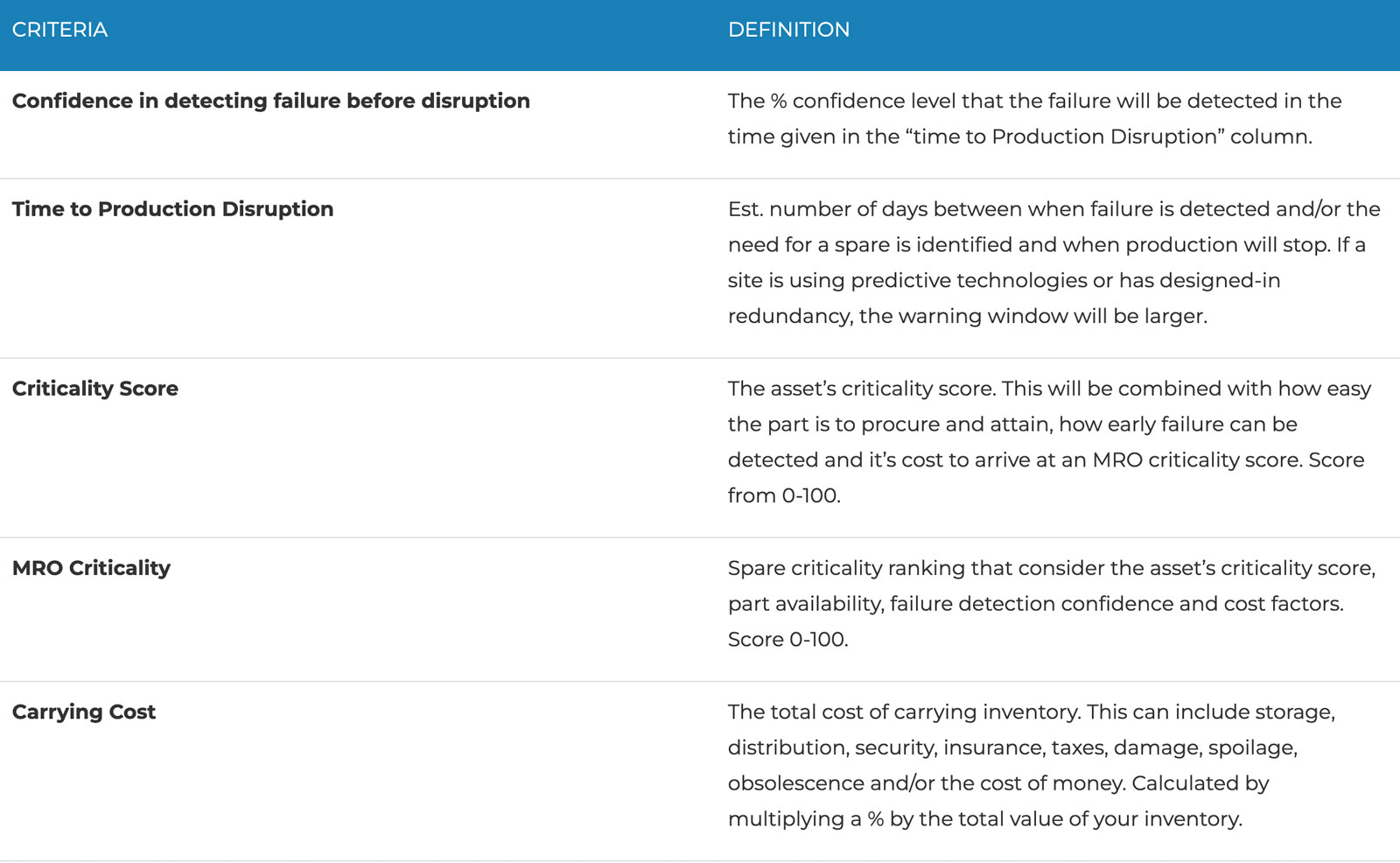

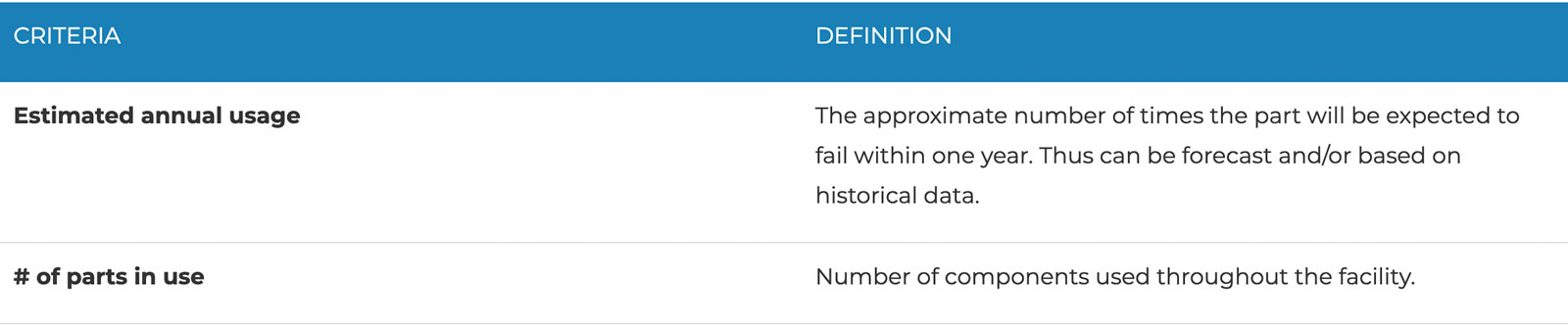

This form can be used to help decide if an item is a critical spare to be stocked. Criteria are weighed to make data driven vs subjective decision based on the risk tolerance of your organization. The form is broken into three main sections: Contact us if you have any questions?

By weighing these factors carefully, you can make data-driven decisions about which spare parts are critical and should be stocked in your inventory. This approach helps optimize your inventory management, ensuring that you have the necessary spare parts on hand to minimize downtime and maintain operational efficiency.

- General Data (completed with support from Reliability Engineers)

- Part Failure Criticality data

- Usage, risk, carrying costs

General Date

Part Failure Criticality Data

Usage, Risk, Carrying Costs

Looking to Advance your EAM Maintenance Strategy? Consider These 4 Tips

If you are in charge of an industrial manufacturing business, then without a doubt you are always seeking ways to advance its key maintenance strategy.

Here at DigitalThinker, we are big proponents of preventative maintenance and in this post, we are going to examine how it is key to monitor your assets in such a way where you are able to identify and correct problems prior to equipment failure—and how preparing and predicting the future has a foundation centered on your ability to harness your data collection practices today.

The Objective

Within the industrial manufacturing sector, the objective of maintenance is always focused on guaranteeing equipment reliability and uptime. It is imperative that you know how machines are working, when they are toeing the line in terms of limitations, and when new equipment must be budgeted for and purchased.

However, accurate equipment forecasting requires data capture, identification, and review within your EAM platform. When you are able to truly understand the data that a platform like Hexagon EAM places at your fingertips, that is when you are able to realize high-quality performance.

So, how do you get to a place where you are able to predict the potential for breakdowns prior to them happening? How do you collect and study data to attain insight that enables improved decision making?

Consider these 4 critical steps you need to take right now in the development of a proactive maintenance program.

-

Data Capture:

It’s never a bad time to start collecting data. And at this point, don’t worry about what to do with it, just start gathering it. Begin small and build upon that. For instance, begin scheduling bearing temperature or pump pressure checks. Plan these out at regular intervals and record the measurements while also sticking to the schedule. If you are able to capture real-time data via your EAM platform, then this allows an advanced approach and will improve your accuracy.

-

Evidence Review:

Once you have your data in hand, study it. Check to see if any patterns are visible that could present an issue or align with operational problems you have been experiencing. And ultimately, the longer that you engage in data capture, the more knowledge you are going to be able to glean when you review it. You will be able to compare data you capture with historical data sets where failures have occurred.

-

Identify Opportunities for Improvement:

After you analyze your data, then you can begin to make predictions about where failure could occur, and you can improve your decision making—in real-time no less—and ultimately avoid machine failure and the downtime that accompanies it. Then, you will be able to create a strategy that allows you to prioritize equipment in need of repair. Once on top of it, you will be able to better plan for downtime and there will be fewer surprises and emergencies.

-

Evaluate:

At the end of the day, your data is only as good as your process is for using it. To truly understand its power, it is necessary for you to visualize and understand it. This means being consistent in your processes, taking time to evaluate what the data is telling you, and then, create your own hypothesis on where problems could lie. And if you have the potential to better use the platform you are collecting data on, then all the better. That is what Hexagon EAM is made for.

To learn how you can take better advantage of Hexagon EAM and its capabilities, or to simply understand how this platform could improve your business, reach out to the team at DigitalThinker today. We are passionate about helping manufacturing organizations get the most bang for their Hexagon EAM buck, and we would love to help your organization be successful.

Seeking to Maximize Trailer ROI? Consider Hexagon EAM

While trying to maximize trailer ROI purchase price, operating cost, and generation of income are all things to consider. Now, the first point, purchase price must be aligned with what the actual trailer is going to haul—that is what is going to determine if there is long term ROI when you couple the other factors along with it. Good maintenance practices impact the latter points—and that is where Hexagon EAM specifically comes in.

Technology’s Impact on Trailer Management

Heavy duty trucks and the way that they are manufactured, managed, and maintained have been greatly impacted by telematics, sensors, and other technologies—and these components are finding their way to the trailer. In essence, trailers are becoming “smart.”

For example, new sensors that are implemented to directly identify maintenance issues and communicate those issues to the driver and operations department in real time are being used more regularly. This allows operators to easily determine just how severe the issue might be and take appropriate action. In turn, operating costs are reduced because the maintenance issue is discovered sooner rather than later, and ROI is enhanced.

Hexagon EAM has the capability of enabling improved communication between assets and their human operators. Without having to rely on feedback from drivers or other sources.

Preventative Maintenance is Key

Tracking preventative maintenance schedules—and sticking to them—is another key component in effective trailer management. Again, this is an area where Hexagon EAM can be a game changer as the platform can ensure trailer uptime and productivity.

So, first, let’s identify the most common causes of trailer breakdowns:

- Tires

- Brake wheel ends

- Lighting

- Liftgates

If a trailer’s tires need to be repaired, while it is sitting in a terminal, that cost usually runs $100 to $150. However, on the road, this expense can be $600 or more! To prevent this expense from occurring tires with low pressure and tire tread issues must be identified first. Hexagon EAM can help guarantee that pre-trip inspections are efficient and effective and will uncover problems before they become a costly emergency.

Hexagon EAM can assist with tracking preventative maintenance on trailers. In turn, operators and fleet managers can prevent:

- The likelihood of a high temperature warning correlating to a brake or wheel-end component failure

- Slow leaks in tires that result in complete tire failure and expensive road service

- Issues with brake line connections, battery failures, and much more

Predict & Prevent Equipment Failure

Hexagon EAM can help your organization maximize the reliability of your trailer assets before equipment failure occurs. This will allow you to carry out preventative maintenance that will keep assets up and running, enabling your organization to meet your business requirements, serve customers, and ensure long-term profitability. Designed to meet your needs, HxGN EAM will scale as your company evolves.

Our team would love to speak with you about how Hexagon EAM can help your fleet operations better manage your trailers, their maintenance schedules, and other initiatives—making downtime and costly repairs a thing of the past. Reach out to DigitalThinker today and let’s start a conversation. Contact us now!

Fleet Management & Hexagon EAM: Improve with Better Data

5 Ways Hexagon EAM Improves Data Quality—and Fleet Management

- Track and Register Vehicle Assets: First off, managing a large fleet presents significant challenges in monitoring and tracking vehicle assets. From warranty management and document organization to performance analysis and service scheduling, the workload can be overwhelming for a single individual or team.

Hexagon EAM can help by:

- Creating a parts inventory

- Tracking warranties and other supporting documentation

- Logging driver data

- Monitoring asset service history

- Plan Preventative Maintenance Schedules: Let’s face it, a breakdown is expensive. Consequently, equipment will always require servicing, it is a much more effective to engage in preventative maintenance, so you can better plan and manage downtime.

Hexagon EAM will:

- Enable you to schedule oil changes and other routine maintenance

- Optimize your maintenance schedule based on unique situations and/or usage

- Track manufacturer specs to ensure recommendations are being followed

- Automated notifications when service is to be performed

With Hexagon EAM you will have the tools necessary to keep your fleet up and running.

- Manage Technicians, Training, and Tools: For instance, any fleet manager worth their salt realizes that they need to know how employees are spending their time, if they are completing work orders correctly, and if they are utilizing tools the right way. With that being said, a fleet manager should actively monitor for mistakes and delays in tasks. These indicators might suggest the need for process or tool training.

With all of this data you will be able to see if your fleet is operating as well as it should be and guarantee that you have the right people doing their jobs efficiently.

- Track Fuel and Vehicle Expenses: No business can afford to waste money or time on fuel or inefficient travel costs. In order to realize the lowest expenditures possible, it is necessary to ensure drivers are not taking inefficient routes through high traffic or construction-addled areas. At this point, you will feel confident knowing that your vehicles are equipped with best-in-class technology.

Hexagon EAM can assist by:

- Providing an on-board computing system that connects drivers to the back office

- Sending real-time route or traffic alerts to drivers

- Outfitting drivers with wearable technology like smart watches, mobile tablets, etc.

- Offering your business the ability to quickly respond to customer service issues regarding real-time delivery issues, etc.

- Manage Parts and Inventory: Also, to manage inventory means that will need to know if inventory levels are properly maintained, while eliminating parts from taking up necessary storage space.

Hexagon EAM will help:

- Manage purchasing processes to get rid of obsolete or redundant inventory

- Keep tabs on regularly reordered parts

- Know your bad actors

- Identify if mechanics require more training on proper parts installation

Ultimately, fleet management professionals need the ability to see data through a highly detailed lens. With Hexagon EAM you will be able to architect a foundation that enables an effective maintenance strategy. Additionally, DigitalThinker welcomes the opportunity to become your partner in this journey. Reach out to our team today and let’s start talking about implementing Hexagon EAM in your fleet management processes. Contact us now.